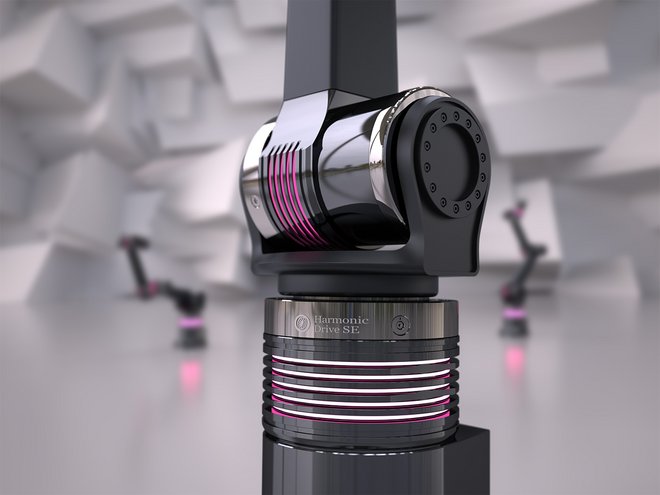

Smart System IHD as compact robot drive system

Actuators and compact systems are the basis for long term developments in the field of digital, intelligent and sensory features. Harmonic Drive SE takes on this task - and presents Smart System IHD.

Drive technology of tomorrow

The need for compactness and intelligence is growing – especially in industrial and mobile drive technology. But when it comes to developing a sustainable and forward-looking machine concept, it is not enough to look solely at current requirements. This is the only way to cover tomorrow's needs comprehensively and smartly.

Key features of the IHD System

- Freedom for programming. With the integrated application processor, the IHD (Intelligent Hollow Shaft Drive) becomes a flexible and progressive Smart System. The processor enables own programming and future applications in the field of condition monitoring.

- Future-oriented, sustainable and efficient, thanks to its software, the IHD is ready for use as a smart system in no time. To master initial positioning tasks, all that is required is to establish a connection via LAN and set application parameters using an intuitive user interface.

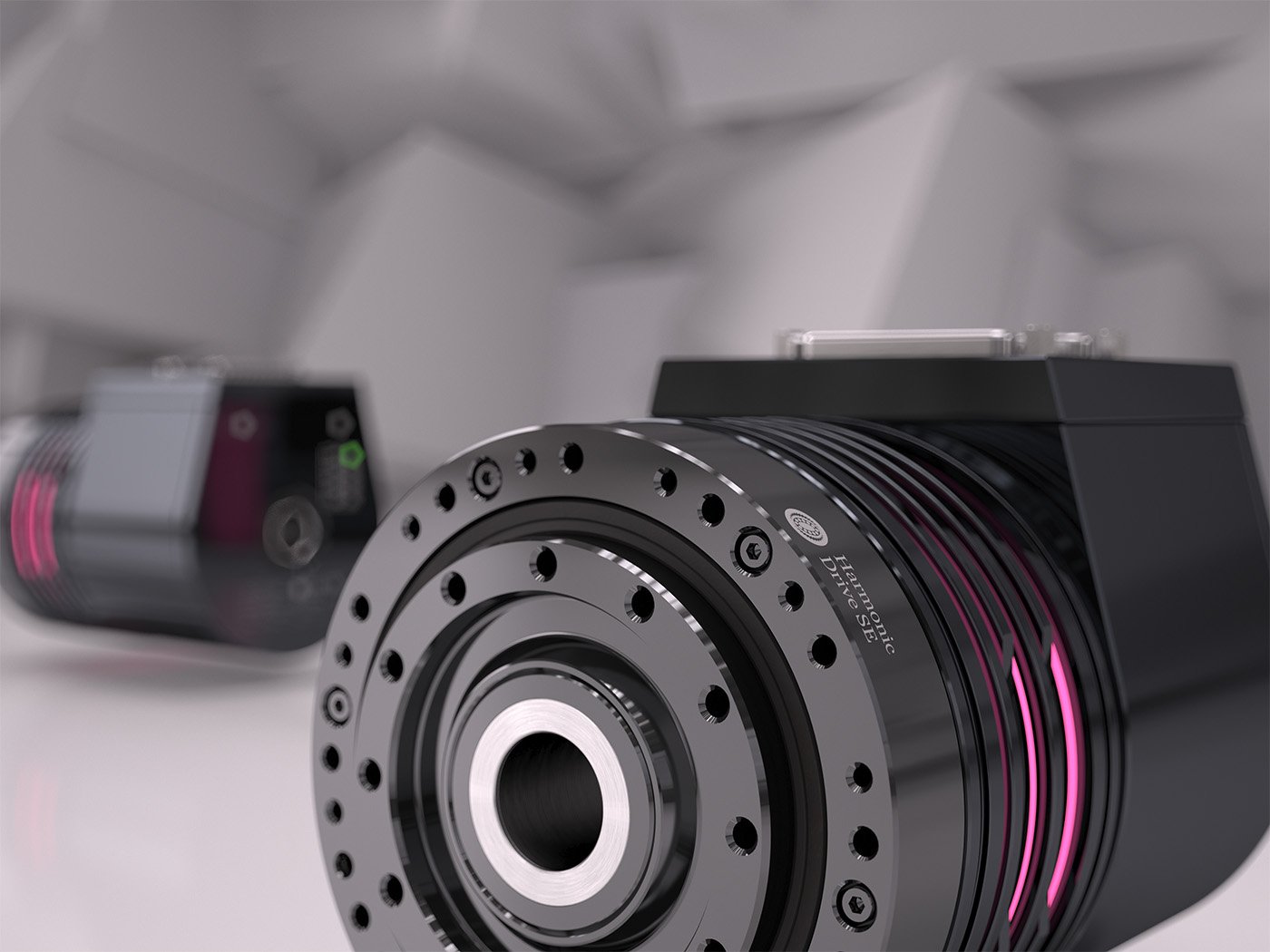

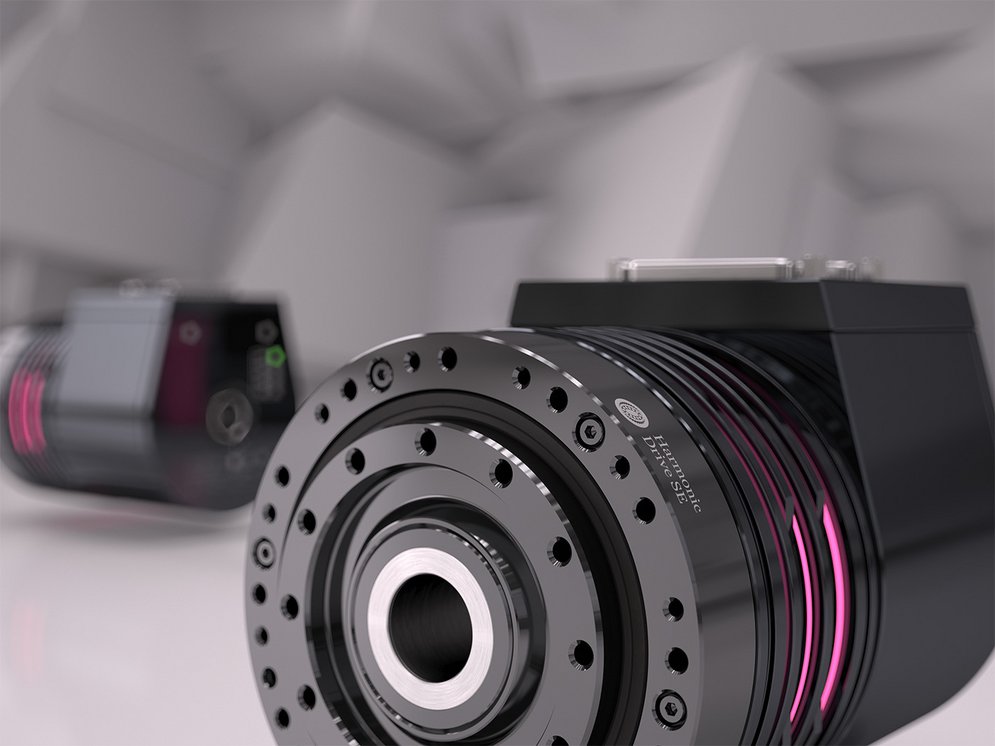

- As rigid as a direct drive and as compact as a geared motor. Thanks to innovative technology, the IHD servo drive system performs highly rigid motion tasks. Precise positioning without the influence of the load from the application.

Solving demanding drive tasks

The development and qualification of the IHD has been successfully completed. During the development process, the compact drive system was optimised in such a way that demanding tasks in the field of stationary and mobile drive technology can be solved. As a Smart System, the IHD is equipped with software tools with the help of which, for example, load or movement cycles can be displayed easily, conveniently and precisely. By means of analytical calculations, the thermal behaviour can also be evaluated quickly and conveniently, even with demanding motion sequences.

Thanks to the ideal interaction of its components, the IHD provides maximum performance for a wide range of applications. In particular, core aspects such as precision and stiffness reach a new level that can even compete with direct drives in some areas. When the load changes during operation, the IHD system is characterised by stable control behaviour and benefits across the board from its compactness and simple control.

Customers and users benefit from using the IHD simultaneously as a sensor for the machine or the entire drive train. The IHD technology platform represents the basis for future tasks in the world of the "Internet of Things".

Technical features

The following technical features characterise IHD actuators:

- Low voltage supply 24/48 VDC

- High torque density

- High absolute positioning accuracy under load

- Gear reduction ratios 50/100/160

- STO functionality

- Digital & analogue input

- Communication interfaces (Ethernet, EtherCAT, CANopen)

- Robust design for use in mobile drive technology

Decentralised drive via daisy chain

The simple commissioning and networking of the IHD systems enables manufacturers to realise new machine concepts. Each system can be assigned an individual address, so that the structure in a large machine network can be easily changed or supplemented depending on the task at hand. Long parts lists and overcrowded control cabinets as well as overloaded cable drag chains are a thing of the past. With the help of a supply voltage in the range of 24/48 VDC, electrical operational safety is also guaranteed without additional measures.

In particular, the IHD software solutions, which have been specially developed and integrated on the basis of the Python programming language, offer a direct and quick introduction. With them, initial programme sequences can be realised - even without PLC control. Not a single line of program code is required for this, so motion sequences are user friendly thanks to the Windows applications developed to control the IHD drive system. The same applies to kinematic evaluation: thanks to various operating modes and positioning tables provided, initial experience with the newly developed machine or kinematics can be obtained - software replaces complex control structures.

Your application, our know-how

Whether communications technology and communication, automation and handling or special environments - as a drive unit, the IHD defies the most diverse circumstances and requirements.

What we know, is the integration of many individual components and parts is tedious. Efforts and complications with controller integration, cabling and EMC behaviour are just examples from a long list. The IHD relieves you of this burden as a system solution, saving not only costs but also valuable time - and doing away with the space-consuming control cabinet. Experience innovation.

A compact and highly integrated all-in-one solution lacks power? The IHD disproves this hypothesis. Thanks to new, segmented winding technology, the AC servo motor of the IHD has a high power density. The thermal optimisation of the IHD design also makes the system the perfect module for high performance applications in both stationary and mobile drive technology.

Did you know?

Save time and space with the all-in-one solution IHD: Thanks to the optimal coordination of motor, gearbox, feedback system, controller and other components, the classic control cabinet is completely unnecessary. The hollow shaft of the servo actuator is also predestined for space savings and maximum freedom of integration

Smart System IHD in figures

Plug and Play via software: The new Smart System IHD from Harmonic Drive SE brings together 50 years of experience with precise gears and state-of-the-art motor and drive technology. IHD drive systems achieve a maximum speed nmax of 19 – 120 [min-1], a maximum torque Tmax of 73 – 120 [Nm] and a reduction ratio i of 50 – 160.

-

0Maximum input speed

-

0Repeated peak torque

-

0Opportunities

The secret of the Harmonic Drive® Gear

It is no longer possible to imagine drive technology without the strain wave gear. Its special features and characteristics explained in detail.

View

Core competence design & development

Highest quality is created with passion. A passion that is realised through deep technical expertise and state-of-the-art processes.

View

Harmonic Drive Gear® explores Mars with Rover Preseverance

The red planet, a mystery? Mars Rover Perseverance uncovers the secrets of our neighbouring planet.

View